Bringing a product to the market requires precise design, high-quality materials, and efficient production. Partnering with plastic forming manufacturers like Plas-Tech ensures your product development process meets these demands. Here are some of the reasons why working with a plastic forming company should be essential for your next project:

Expertise & Technical Knowledge

Plastic forming manufacturers like Plas-Tech possess specialised knowledge of materials, processes, and design considerations. This expertise ensures your product is functional, durable, and aesthetically pleasing. At Plas-Tech, our experienced team provides plastic forming solutions to meet your exact specifications, offering everything from design support to resolving technical issues.

Access to Advanced Equipment & Technology

Investing in cutting-edge technology is a priority for any leading plastic forming company. We at Plas-Tech operate state-of-the-art vacuum forming machines and 5-axis CNC trimming systems, guaranteeing precise, consistent, and efficient work. This advanced equipment allows for complex geometries, tight tolerances, and a wide range of finishes.

Comprehensive In-House Services

One of the key benefits of working with a plastic forming company like Plas-Tech is access to a full suite of in-house services. From initial design and prototyping to tooling, production, and assembly, we manage every step under one roof. This integrated approach minimises lead times, reduces costs, and ensures seamless communication throughout the project.

Material Selection & Customisation

Choosing the right material is crucial for product performance. Plastic forming manufacturers offer a vast selection of materials, including ABS, polypropylene, and polycarbonate. At Plas-Tech, we help you select the best material for your application, considering factors such as strength, flexibility, and environmental conditions. Our custom colour options and textured finishes allow for unique, high-quality products.

Rapid Prototyping & Iteration

Bringing a new product to the market often involves multiple design iterations. Plastic forming services provide rapid prototyping solutions to speed up this process. Plas-Tech’s in-house Ureol prototyping allows for quick design validation, helping you refine your product before full-scale production begins.

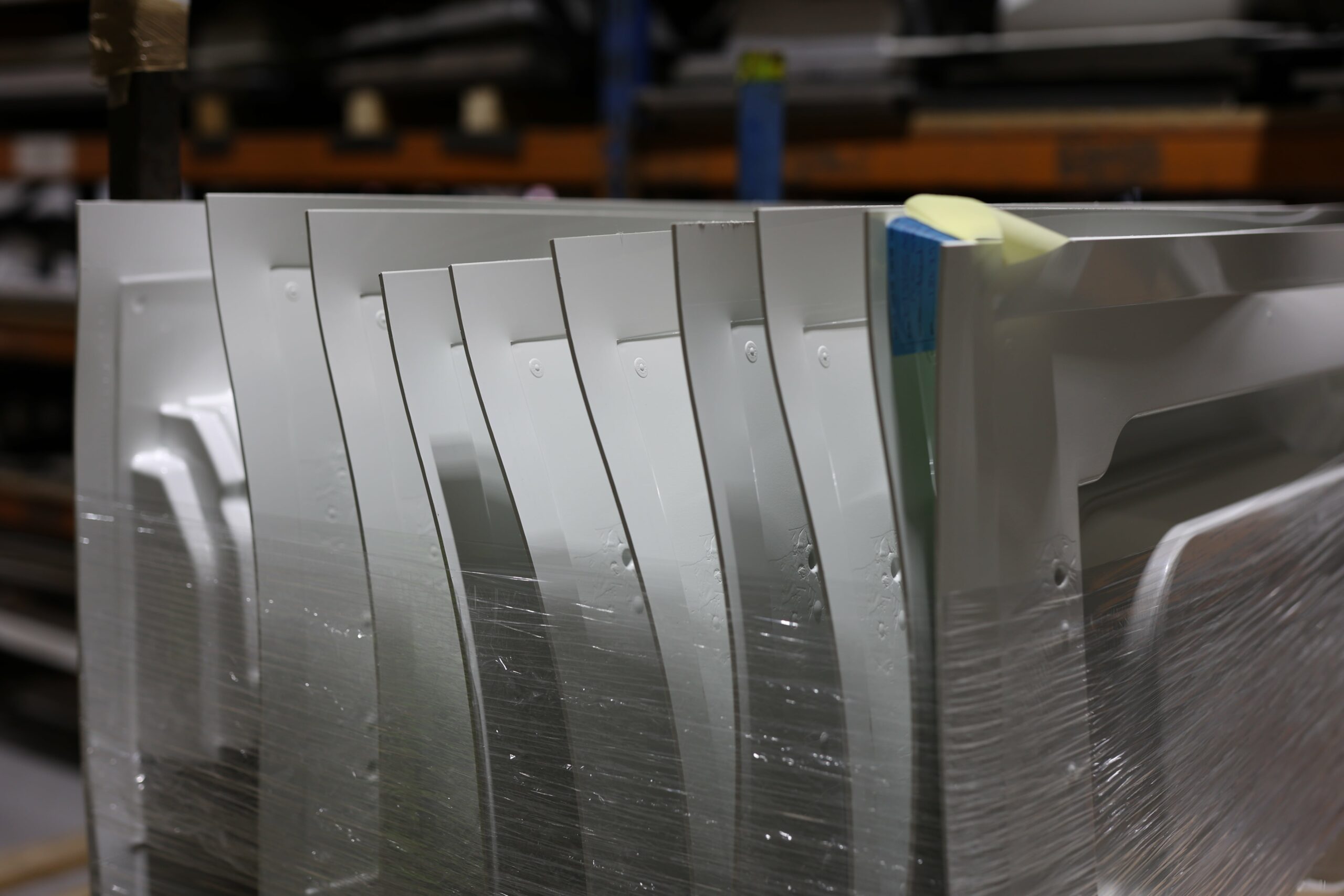

Scalability & Flexibility

Whether you need a batch of prototypes or high-volume production, plastic forming manufacturers offer the flexibility to scale operations as needed. Plas-Tech’s 24/7 production capabilities and automated systems guarantee we can meet your demands, from medium-volume custom components to mass production runs.

Quality Assurance & Reliability

Ensuring product quality is non-negotiable. Plastic forming manufacturers adhere to strict quality control standards. Plas-Tech is ISO 9001:2015 certified, guaranteeing consistent quality, reliability, and compliance with industry standards. Our rigorous process management makes sure every component meets your specifications.

An Expert Plastic Forming Manufacturer for Your Next Project

Choosing the right plastic forming manufacturer can make or break your product development process. At Plas-Tech, we offer decades of experience, cutting-edge technology, and a full suite of in-house services to bring your vision to life.

Contact us today to learn how our UK plastic forming services can support your next project.