What is Vacuum Forming?

Vacuum forming is a method of plastic moulding which involves using heat, vacuum and air to produce a particular shape from plastic.

How Does it vacuum forming Work?

This process starts with an extruded thermoplastic sheet which is laid flat and heated to around 170 degrees celcius. It is then blown with air and placed onto the mould tool, before a vacuum removes the air and leaves behind a perfect, precise mould.

What Parts Can be Vacuum Formed?

Vacuum forming has very few limitations and can be used to cost-effectively produce a huge range of products and parts including automotive components, enclosures and trays, POS retail display, packaging and stage props. It can also be used for rapid prototyping for new product development.

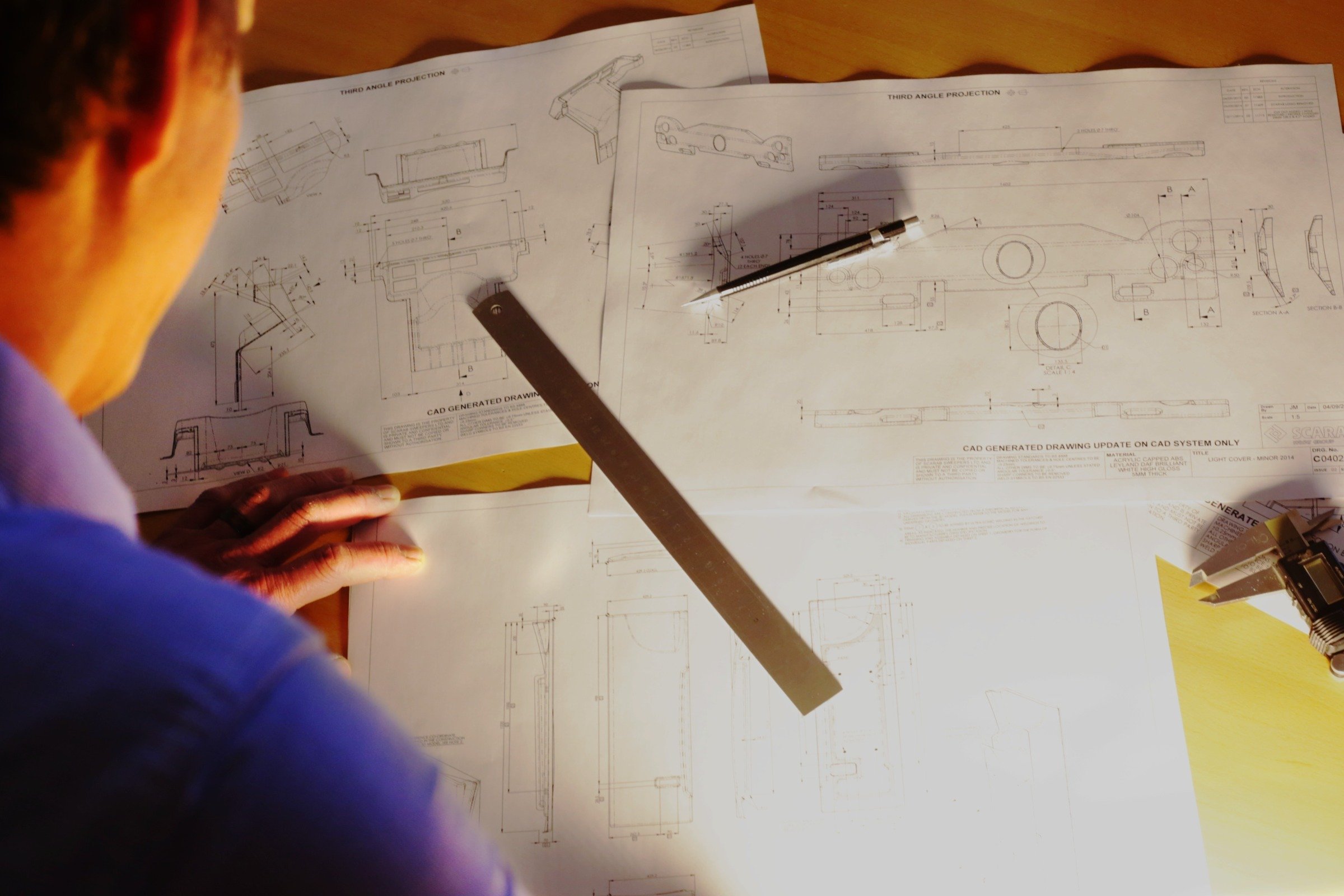

Can You Help With Design?

As a vacuum forming plastics company, we specialise in and encourage design flexibility. We house a full capability suite of prototype tool manufacture managed by a team of experts who can help you refine your final production design. We have advanced CAD/CAM machining centres to help you achieve the right design in a short amount of time.

What Finish Can I Expect?

Our thermoforming specialists offer vacuum forming in a range of textures and finishes from embossed and high gloss, to soft feel and decorative foils. We are also able to offer a selection of both stock and custom colours. For more information or to enquire, please contact us on 01964 544544.

Ends.