Capabilities

- Automated Loading for volume production

- 24-Hour 7-days a week Production

- four vacuum forming machines up to 2.4 x 1.4 metres

- Handling small to large components

- Processing materials including ABS, HIPS, Polypropylene, HDPE, Polycarbonate

- Custom colours and stock colours

- Multiple textures and finishes, including embossed, high gloss, soft feel, and decorative foils

- ISO 9001: 2015 certified

At Plas-Tech, we specialise in the production of high-quality vacuum-formed plastic components using our state-of-the-art equipment and extensive experience. Our 132-hour operating week, spanning Monday to Thursday 24 hours with a full 36-hour shift on weekends, ensures we meet the demands of our customers, never leaving them without the parts they require.

Our four vacuum forming machines, capable of moulding up to 2.4 x 1.4 metres, cater to a wide range of applications, from low-to-high volume production. We currently handle annual production runs from 200 pieces per annum to over 40,000 pieces per annum for specific components.

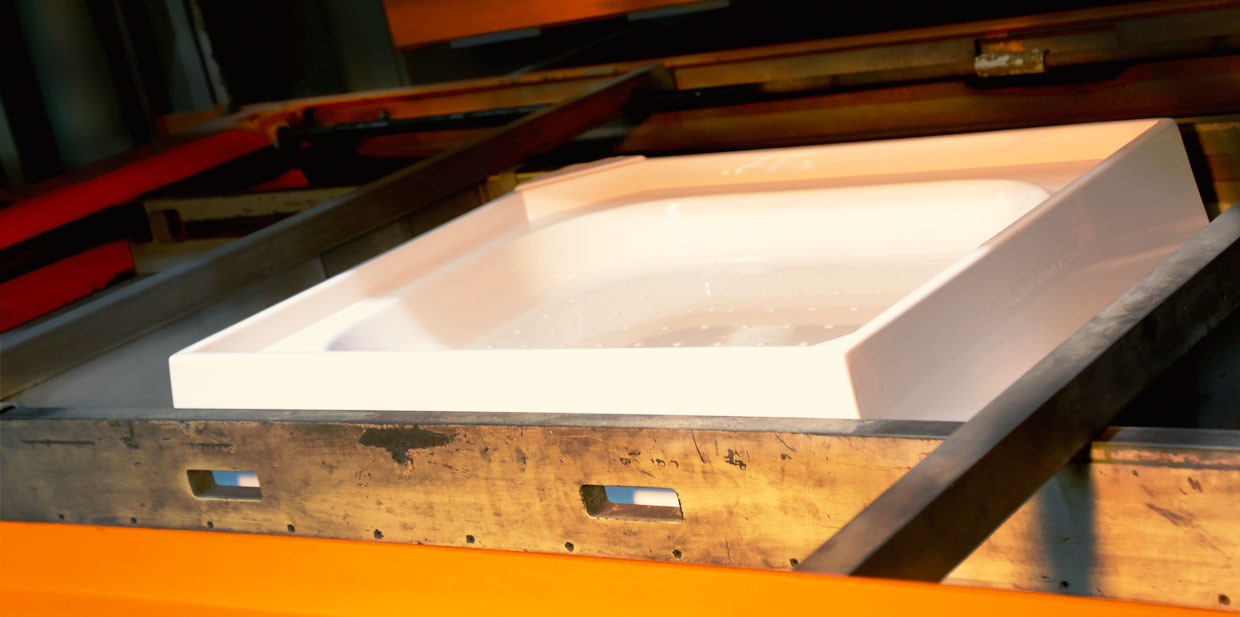

Focusing on heavy-gauge vacuum forming, we handle sheet thickness starting from 1.5mm to 8mm extruded sheet. Our most prominent market sector lies in manufacturing exterior or interior automotive and off-highway vehicle body panels, coverings, shower trays, demanding intricate details and robust construction.

Our in-house tooling capabilities include a complete aluminium machining centre capable of processing billets over 1500 mm in length. We handle all machining, jig, and pattern-making in-house, ensuring seamless integration and control over the process. Additionally, we can produce external casting tools upwards of 2.4 metres in length.

To expedite the tooling process, we offer full Ureol prototyping in-house. This cost-effective and rapid turnaround option proves invaluable when urgent or new tooling is required. Our control over tool manufacture allows us to flexibly accommodate your needs.

Plas-Tech prides itself on its professional and personalised service, flexibility, and commitment to delivering projects to the highest standards. Whether you need bespoke design solutions, technical issue resolution, rapid prototyping, or a reliable manufacturing partner, we can provide you with the expertise and support you require.