New CMS Machines at Plas Tech

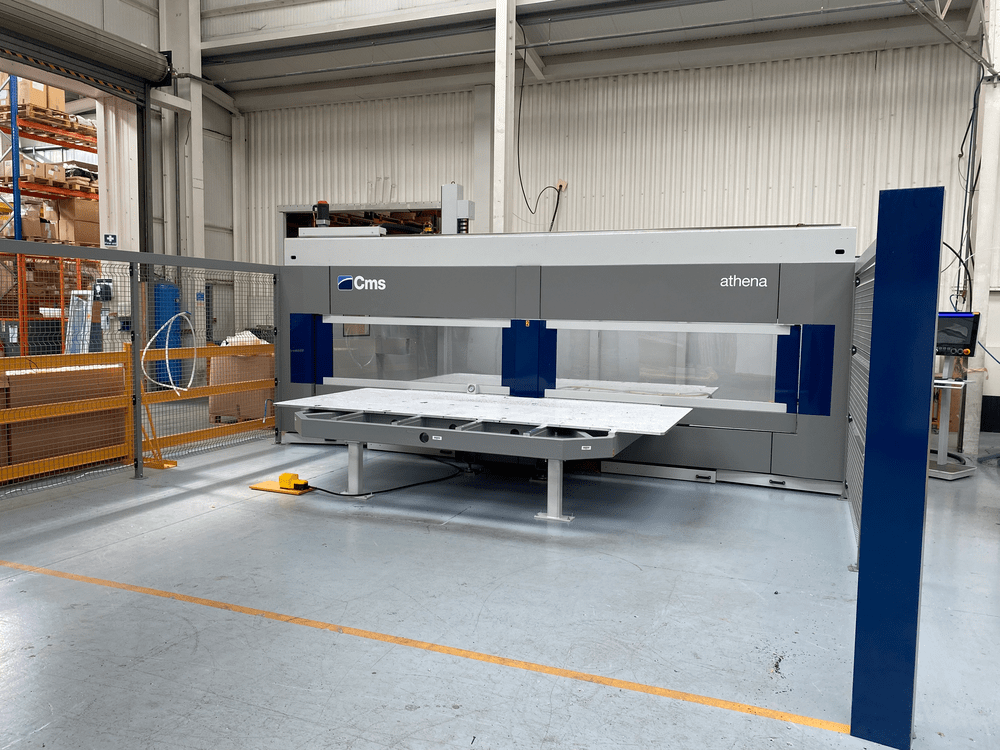

Over the last year, we have invested in three new CMS machines at Plas Tech. As part of a large investment programme for the business, we undertook the decision to replace our previous range of MAKA CNC machines. Based on the experience from our first CMS Ares machine which we purchased in 2019.

This first machine was dedicated to the manufacture of our in-house jig and tooling. We further adapted the use of the machine as a production machine to trim plastic when we needed the additional capacity. Through the performance and usability of the machine, it gave us the confidence to move forward with CMS as our main CNC machine supplier.

With the improved reliability, the machines have given us the confidence to expand our 24-hour operation and move the CNC team into operating over the weekends as well as weekdays. The new rotating table designs, which we custom-specified with CMS gives us the ability to run and load new jobs at the same time, thus giving us no downtime in the cycle.

Through the improvement of consistent machine reliability and a drive to grow our order book, these new machines have been a vital element for our continued growth as a forward-thinking, proactive business.